[ad_1]

Typically, researchers seeking to synthesize specifically targeted material particles have had to rely on intuition or trial-and-error methods. This approach can be inefficient and requires a significant investment of time and resources.

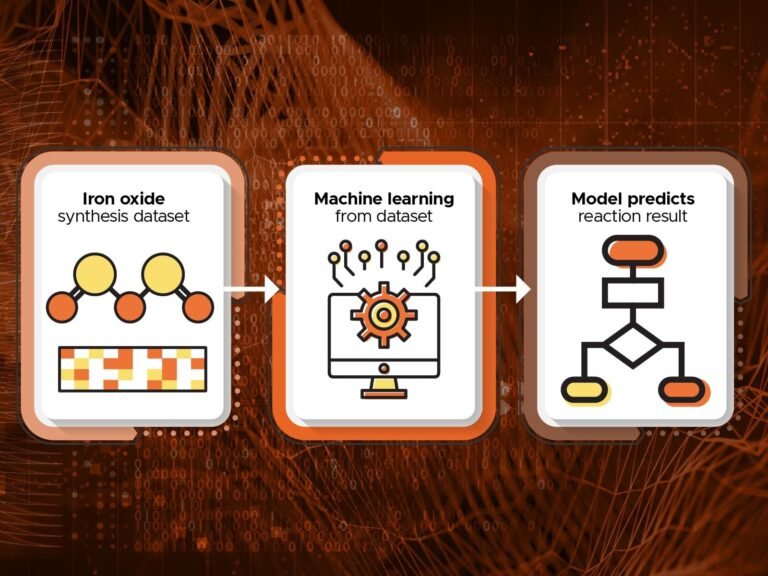

To overcome the ambiguity of this approach, PNNL researchers harnessed the power of data science and ML techniques to streamline the synthetic development of iron oxide particles. This study chemical engineering journal.

Their approach addressed two critical issues: identifying viable experimental conditions and predicting potential particle properties for a given set of synthesis parameters. The trained model predicts potential particle sizes and phases over a range of experimental conditions and identifies promising and feasible synthesis parameters to explore.

This innovative approach represents a paradigm shift in metal oxide particle synthesis and has the potential to significantly save time and effort spent on ad hoc iterative synthesis approaches. By training an ML model based on careful experimental characterization, this approach demonstrated remarkable accuracy in predicting iron oxide outcomes based on synthesis reaction parameters. The search and ranking algorithms provided reasonable reaction conditions to explore from the input dataset. We also uncovered the previously overlooked importance of the pressure applied during synthesis on the resulting phase and particle size.

For more information:

Juejing Liu et al., Phase and Size Controlled Synthesis of Iron Oxide Particles Using Machine Learning, chemical engineering journal (2023). DOI: 10.1016/j.cej.2023.145216

[ad_2]

Source link